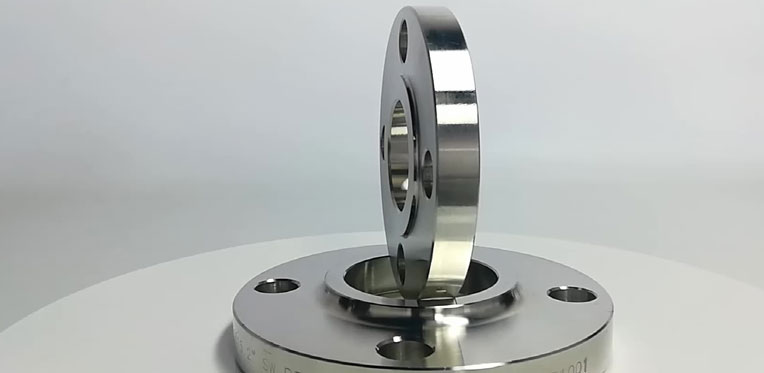

ANSI B16.5 / ASME B16.47 Stainless Steel Slip on Flange Manufacturers

ASME B16.5 Slip on Flanges Suppliers

Experts in Manufacturing of ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS 10, BS4504, API 605, EN-1092, DIN SO Flange, SORF Flange, SOFF Flange in Class 150#, 300#, 600#, 900#, 1500#, 2500#, Pressure PN6, PN10, PN16, PN25, PN40, PN64.

Professional and most reliable Exporters and Suppliers of Stainless Steel Slip On Plate Flange, ASME SA182 / ASTM A182 SS Slip on Flange 304, 316 Flanges all over the world but highly demanded in Iran, Thailand, Kuwait, Oman, US, UK, Iraq, Turkey, UAE (Dubai), Italy, Vietnam, Bhutan, Qatar.

To Satisfy the urgent need of the customers we keep intensive stock of Flat Face and Raised Face Slip on Flanges Manufactured using different standards like DIN, EN1092-1, UNI, API 6A, ANSI, ASME B16.47 Series A & B, AWWA C207, GOST, BS10, PSI, GB, JIS/KS, BS4504 Flange in all Dimensions and Classes.

A flange is a cast ring or forged of steel designed to connect mechanically two sections of steel pipe or join pipe to a pressure pump, vessel, valve or any other piece of equipment. Same standard flanges can either be flat face or raised face.

Aakash Steel is one of the prominent supplier and Exporter of Stainless Steel Flanges most demanding grades are SS 304, 304L, 316, 316L, and 904L. Stainless steel is one of the most popular and demanding metals from our client. Due to its physical properties including good corrosion resistance, durability, and many others, this metal scores over several other metals.

Slip on Flanges Specifications

| Product | SO Flange / SORF Flange / SOFF Flange |

|---|---|

| Size | ½” (15 NB) to 48″ (1200NB) |

| Class | 2500 LBS, 1500 LBS, 900 LBS, 600 LBS, 300 LBS, 150 LBS, DIN Standard ND-6, 10, 16, 25, 40 Etc. |

| DIN | DIN2673, DIN2638, DIN2637, DIN2636, DIN2635, DIN2634, DIN2633, DIN2632, DIN2631, DIN2629, DIN2628, DIN2627, DIN2656, DIN2655, DIN2642, DIN2641, DIN2576, DIN2573, DIN2566, DIN2527 |

| BS | BS4504, BS4504, BS1560, BS10 |

| In Form | LAP Joint, Threaded, Reducing, Spectacle, SORF, WNRF, BLRF, SWRF, etc |

| Standard | ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, DIN, JIS, SABS1123, GOST-12820, BS 4504, EN1092, UNI 2277/2278 |

| Coating/Surface Treatment | Anti-rust Paint, Zinc Plated, Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized |

| Types of Connection | Lap-Joint Face, Raised Face, Ring Type Joint, Flat Face, Large Male-Female, Small Male-Female, Large, Small Tongue & Groove |

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Joint (RJT) |

| Dimensions | ANSI B16.47 Series A & B, ANSI B16.5, MSS SP44, ASA, API-605, AWWA |

| Flange Packing | No Fumigate or Fumigate Plywood/Wood Pallet or Case |

| Usage/Applications | Offshore, Water System, Oil Field, Natural Gas, Shipbuilding, Electric Power, Pipe Projects, etc. |

| Common types of Flanges | Forged / Screwed / Threaded / Plate |

| Production Technique | Forged, Heat treated and machined |

| Value-Added Services: | CNC Machining, Customised Flanges |

| We are Specialize in Making Flanges As Per The Drawings | |

Slip on Flange Manufacturing Materials & Grades

| Stainless Steel Slip on Flange | Equivalent Grades | Chemical Composition | Mechanical Properties |

|---|

| ASTM A182, A240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L, 202. |

| Alloy Steel Slip on Flange | Chemical Composition | Mechanical Properties | ASTM A182 |

| ASTM A182 / ASME SA182 & A387 F1, F5, F9, F11, F12, F22, F91. |

| Carbon Steel Slip on Flange | Chemical Composition | Mechanical Properties |

| ASTM A105 / ASME SA105, ASTM A350 / ASME SA350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52. |

| Other Steel Slip on Flange | Chemical Composition | Mechanical Properties | Equivalent Grades |

| Alloy 20, Alloy C, Alloy C276, Alloy B2, SMO 254, AISI 4130. |

| Low-Temperature Steel Slip on Flange |

| ASTM A350 LF2, LF3, LF6. |

| High Yield Slip on Flange |

| ASTM A694 F42, F52, F60, F65, F70. |

| Duplex Steel Slip on Flange | Chemical Composition | Mechanical Properties | Equivalent Grades |

| ASTM / ASME A/SA 182 F 44, F 45, F 51, F 53, F 55, F 60, F 61. |

| Super Duplex Slip on Flange | Chemical Composition | Mechanical Properties | Equivalent Grades |

| ASTM / ASME A/SA 182 F 44, F 45, F 51, F 53, F 55, F 60, F 61. |

| Copper Alloy Slip on Flange | Chemical Composition | Mechanical Properties | Equivalent Grades |

| ASTM SB 61, SB62, SB151, SB152 – UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200. |

| Nickel Alloy Slip on Flange | Chemical Composition | Mechanical Properties | Equivalent Grades |

| ASTM SB564, SB160, SB472, SB162 – Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020). |

ANSI/ASME B16.5 Slip on Flange Dimensions / Slip On Plate Flange Dimensions

CLASS 150 LBS SLIP ON FLANGE DIMENSIONS

| ANSI/ASME/ASA B16.5 150lb/sq.in. Flange SO-RF | ||||||||||

| ø | D | b | g | m | J | h | k | Holes | l | Kg. |

| 1/2″ | 88,9 | 11,1 | 34,9 | 30,2 | 22,3 | 15,9 | 60,3 | 4 | 15,9 | 0,400 |

| 3/4″ | 98,4 | 12,7 | 42,9 | 38,1 | 27,7 | 15,9 | 69,8 | 4 | 15,9 | 0,700 |

| 1″ | 107,9 | 14,3 | 50,8 | 49,2 | 34,5 | 17,5 | 79,4 | 4 | 15,9 | 0,800 |

| 1 1/4″ | 117,5 | 15,9 | 63,5 | 58,8 | 43,2 | 20,6 | 88,9 | 4 | 15,9 | 1,100 |

| 1 1/2″ | 127,0 | 17,5 | 73,0 | 65,1 | 49,5 | 22,2 | 98,4 | 4 | 15,9 | 1,400 |

| 2″ | 152,4 | 19,0 | 92,1 | 77,8 | 62,0 | 25,4 | 120,6 | 4 | 19,0 | 2,200 |

| 2 1/2″ | 177,8 | 22,2 | 104,8 | 90,5 | 74,7 | 28,6 | 139,7 | 4 | 19,0 | 3,600 |

| 3″ | 190,5 | 23,8 | 127,0 | 107,9 | 90,7 | 30,2 | 152,4 | 4 | 19,0 | 4,100 |

| 3 1/2″ | 215,9 | 23,8 | 139,7 | 122,2 | 103,4 | 31,7 | 177,8 | 8 | 19,0 | 5,200 |

| 4″ | 228,6 | 23,8 | 157,2 | 134,9 | 116,1 | 33,3 | 190,5 | 8 | 19,0 | 5,600 |

| 5″ | 254,0 | 23,8 | 185,7 | 163,6 | 143,8 | 36,5 | 215,9 | 8 | 22,2 | 6,300 |

| 6″ | 279,4 | 25,4 | 215,9 | 192,1 | 170,7 | 39,7 | 241,3 | 8 | 22,2 | 7,500 |

| 8″ | 342,9 | 28,6 | 269,9 | 246,1 | 221,5 | 44,4 | 298,4 | 8 | 22,2 | 12,600 |

| 10″ | 406,4 | 30,2 | 323,8 | 304,8 | 276,3 | 49,2 | 361,9 | 12 | 25,4 | 18,500 |

| 12″ | 482,6 | 31,7 | 381,0 | 365,1 | 327,1 | 55,6 | 431,8 | 12 | 25,5 | 28,000 |

| 14″ | 533,4 | 34,9 | 412,7 | 400,0 | 359,1 | 57,1 | 476,2 | 12 | 28,6 | 36,000 |

| 16″ | 596,9 | 36,5 | 469,9 | 457,2 | 410,5 | 63,5 | 539,7 | 16 | 28,6 | 46,000 |

| 18″ | 635,0 | 39,7 | 533,4 | 504,8 | 461,8 | 68,3 | 577,8 | 16 | 31,7 | 50,000 |

| 20″ | 698,5 | 42,9 | 584,2 | 558,8 | 513,1 | 73,0 | 635,0 | 20 | 31,7 | 64,000 |

| 22″ | 749,3 | 46,0 | 641,2 | 609,6 | 564,4 | 79,4 | 692,1 | 20 | 34,9 | 72,000 |

| 24″ | 812,8 | 47,6 | 692,1 | 663,6 | 615,9 | 82,5 | 749,3 | 20 | 34,9 | 89,000 |

CLASS 300 LBS SLIP ON FLANGE DIMENSIONS

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

|---|---|---|---|---|---|---|---|---|---|

| 1/2″ | 21.3 | 12.7 | 35.05 | 38 | 22.2 | 21 | 4 | 15.87 | 66.7 |

| 3/4″ | 26.7 | 14.3 | 42.93 | 48 | 27.7 | 24 | 4 | 19.05 | 82.6 |

| 1″ | 33.4 | 15.9 | 50.80 | 54 | 34.5 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4″ | 42.2 | 17.5 | 63.50 | 64 | 43.2 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2″ | 48.3 | 19.1 | 73.15 | 70 | 49.5 | 29 | 4 | 22.22 | 114.3 |

| 2″ | 60.3 | 20.7 | 91.95 | 84 | 61.9 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2″ | 73.0 | 23.9 | 104.65 | 100 | 74.6 | 37 | 8 | 22.22 | 149.2 |

| 3″ | 88.9 | 27.0 | 127.00 | 117 | 90.7 | 41 | 8 | 22.22 | 168.3 |

| 3 1/2″ | 101.6 | 28.6 | 139.70 | 133 | 103.4 | 43 | 8 | 22.22 | 184.2 |

| 4″ | 114.3 | 30.2 | 157.22 | 146 | 116.1 | 46 | 8 | 22.22 | 200.0 |

| 5″ | 141.3 | 33.4 | 185.67 | 178 | 143.8 | 49 | 8 | 22.22 | 235.0 |

| 6″ | 168.3 | 35.0 | 215.90 | 206 | 170.7 | 51 | 12 | 22.22 | 269.9 |

| 8″ | 219.1 | 39.7 | 269.75 | 260 | 221.5 | 60 | 12 | 25.40 | 330.2 |

| 10″ | 273.0 | 46.1 | 323.85 | 321 | 276.2 | 65 | 16 | 28.57 | 387.4 |

| 12″ | 323.8 | 49.3 | 381.00 | 375 | 327.0 | 71 | 16 | 31.75 | 450.8 |

| 14″ | 355.6 | 52.4 | 412.75 | 425 | 359.2 | 75 | 20 | 31.75 | 514.4 |

| 16″ | 406.4 | 55.6 | 469.90 | 483 | 410.5 | 81 | 20 | 34.92 | 571.5 |

| 18″ | 457.0 | 58.8 | 533.40 | 533 | 461.8 | 87 | 24 | 34.92 | 628.6 |

| 20″ | 508.0 | 62.0 | 584.2td> | 587 | 513.1 | 94 | 24 | 34.92 | 685.8 |

| 24″ | 610.0 | 68.3 | 692.15 | 702 | 616.0 | 105 | 24 | 41.27 | 812.8 |

CLASS 600 LBS SLIP ON FLANGE DIMENSIONS

| ANSI/ASME/ASA B16.5 600lb/sq.in. Flange WN-RF | ||||||||||

| ø | D | b | g | m | J | h | k | Holes | l | Kg. |

| 1/2″ | 95,2 | 14,3 | 34,9 | 38,1 | 22,3 | 22,2 | 66,7 | 4 | 15,9 | 0,800 |

| 3/4″ | 117,5 | 15,9 | 42,9 | 47,6 | 27,7 | 25,4 | 82,5 | 4 | 19,0 | 1,400 |

| 1″ | 123,8 | 17,5 | 50,8 | 54,0 | 34,5 | 27,0 | 88,9 | 4 | 19,0 | 1,600 |

| 1 1/4″ | 133,3 | 20,6 | 63,5 | 63,5 | 43,2 | 28,6 | 98,4 | 4 | 19,0 | 2,100 |

| 1 1/2″ | 155,6 | 22,2 | 73,0 | 69,8 | 49,5 | 31,7 | 114,3 | 4 | 22,2 | 3,100 |

| 2″ | 165,1 | 25,4 | 92,1 | 84,1 | 62,0 | 36,5 | 127,0 | 8 | 19,0 | 3,700 |

| 2 1/2″ | 190,5 | 28,6 | 104,8 | 100,0 | 74,7 | 41,3 | 149,2 | 8 | 22,2 | 5,400 |

| 3″ | 209,5 | 31,7 | 127,0 | 117,5 | 90,7 | 46,0 | 168,3 | 8 | 22,2 | 7,300 |

| 3 1/2″ | 228,6 | 34,9 | 139,7 | 133,3 | 103,4 | 49,2 | 184,1 | 8 | 25,4 | 8,900 |

| 4″ | 273,0 | 38,1 | 157,2 | 152,4 | 116,1 | 54,0 | 215,9 | 8 | 25,4 | 11,800 |

| 5″ | 330,2 | 44,4 | 185,7 | 188,9 | 143,8 | 60,3 | 266,7 | 8 | 28,6 | 24,500 |

| 6″ | 355,6 | 47,6 | 215,9 | 222,2 | 170,7 | 66,7 | 292,1 | 12 | 28,6 | 29,500 |

| 8″ | 419,1 | 55,6 | 269,9 | 273,0 | 221,5 | 76,2 | 349,2 | 12 | 31,7 | 43,000 |

| 10″ | 508,0 | 63,5 | 323,8 | 342,8 | 276,3 | 85,7 | 431,8 | 16 | 34,9 | 70,000 |

| 12″ | 558,8 | 66,7 | 381,0 | 400,0 | 327,1 | 92,1 | 488,9 | 20 | 34,9 | 86,000 |

| 14″ | 603,2 | 69,8 | 412,7 | 431,8 | 359,1 | 93,7 | 527,0 | 20 | 38,1 | 100,000 |

| 16″ | 685,8 | 76,2 | 469,9 | 495,3 | 410,5 | 106,4 | 603,2 | 20 | 41,3 | 142,000 |

| 18″ | 742,9 | 82,5 | 533,4 | 546,1 | 461,8 | 117,5 | 654,0 | 20 | 44,4 | 175,000 |

| 20″ | 812,8 | 88,9 | 584,2 | 609,6 | 513,1 | 127,0 | 723,9 | 24 | 44,4 | 232,000 |

| 22″ | 869,9 | 95,2 | 641,2 | 666,7 | 564,4 | 133,3 | 777,9 | 24 | 47,6 | 292,000 |

| 24″ | 939,8 | 101,6 | 692,1 | 717,5 | 615,9 | 139,7 | 838,2 | 24 | 50,8 | 330,000 |

DIN 86029 PN10 HUBBED SLIP ON FLANGE DIMENSIONS

| Rated Diameter | O.D. of Pipe | Flange Parameter | Neck Size | Size of R.F. | Bolts | Approx. Weight | |||||||

| DN | d1 | D | d5 | b | k | h | d3 | r | d4 | f | No. of holes |

d2 | KG |

| 10 | 17.2 | 90 | 17.7 | 14 | 60 | 20 | 30 | 4 | 40 | 2 | 4 | 14 | 0.56 |

| 15 | 21.3 | 95 | 22 | 14 | 65 | 20 | 35 | 4 | 45 | 2 | 4 | 14 | 0.62 |

| 20 | 26.9 | 105 | 27.6 | 16 | 75 | 24 | 45 | 4 | 58 | 2 | 4 | 14 | 0.91 |

| 25 | 33.7 | 115 | 34.4 | 16 | 85 | 24 | 52 | 5 | 68 | 2 | 4 | 14 | 1.09 |

| 32 | 42.4 | 140 | 43.1 | 16 | 100 | 26 | 60 | 5 | 78 | 2 | 4 | 18 | 1.58 |

| 40 | 48.3 | 150 | 49 | 16 | 110 | 26 | 70 | 5 | 88 | 3 | 4 | 18 | 1.76 |

| 50 | 60.3 | 165 | 61.1 | 18 | 125 | 28 | 85 | 5 | 102 | 3 | 4 | 18 | 2.39 |

| 65 | 76.1 | 185 | 77.1 | 18 | 145 | 32 | 105 | 5 | 122 | 3 | 4 | 18 | 3.1 |

| 80 | 88.9 | 200 | 90.3 | 20 | 160 | 34 | 118 | 5 | 138 | 3 | 8 | 18 | 3.77 |

| 100 | 114.3 | 220 | 115.9 | 20 | 180 | 38 | 140 | 5 | 158 | 3 | 8 | 18 | 4.29 |

| 125 | 139.7 | 250 | 141.6 | 22 | 210 | 40 | 168 | 5 | 188 | 3 | 8 | 18 | 5.86 |

| 150 | 168.3 | 285 | 170.5 | 22 | 240 | 44 | 196 | 5 | 212 | 3 | 8 | 22 | 7.22 |

| 175 | 193.7 | 315 | 196.1 | 24 | 270 | 44 | 224 | 6 | 242 | 3 | 8 | 22 | 9.18 |

| 200 | 219.4 | 340 | 222 | 24 | 295 | 44 | 247 | 6 | 268 | 3 | 8 | 22 | 9.95 |

| 250 | 273 | 395 | 276 | 26 | 350 | 46 | 300 | 6 | 320 | 3 | 12 | 22 | 12.69 |

| 300 | 323.9 | 445 | 327 | 26 | 400 | 46 | 352 | 6 | 370 | 4 | 12 | 22 | 14.4 |

| 350 | 355.6 | 505 | 359 | 26 | 460 | 53 | 398 | 10 | 430 | 4 | 16 | 22 | 22.36 |

| 400 | 406.4 | 565 | 410 | 26 | 515 | 57 | 448 | 10 | 482 | 4 | 16 | 26 | 26.85 |

| 450 | 457 | 615 | 461 | 28 | 565 | 62 | 502 | 10 | 532 | 4 | 20 | 26 | 32.53 |

| 500 | 508 | 670 | 512 | 28 | 620 | 67 | 552 | 10 | 585 | 4 | 20 | 26 | 37.84 |

| 600 | 610 | 780 | 614 | 28 | 725 | 75 | 658 | 10 | 685 | 5 | 20 | 30 | 49.32 |

| 700 | 711 | 895 | 716 | 30 | 840 | 77 | 760 | 10 | 800 | 5 | 24 | 30 | 63.86 |

| 800 | 813 | 1015 | 818 | 32 | 950 | 84 | 864 | 10 | 905 | 5 | 24 | 33 | 85.19 |

| 900 | 914 | 1115 | 920 | 34 | 1050 | 88 | 969 | 10 | 1005 | 5 | 28 | 33 | 101.4 |

| 1000 | 1016 | 1230 | 1022 | 34 | 1160 | 92 | 1071 | 10 | 1110 | 5 | 28 | 36 | 119.7 |

ANSI B16.5 Slip-on Flange Dimensional Tolerances

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter ≤ 10 = ± 0.8 mm | ≥ 12 = + 1.6 mm / – 0 mm |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore Same as for Inside Diameter |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

Prime Countries Where We Supply & Export

Aakash Steel is an ISO, OHSAS, and PED Certified Company largely engage in manufacturing, stocking, exporting, and supplying of ASTM A182 SS 304/316 Slip on Flanges in domestic and overseas. We produce these ANSI/ASME B16.5 SO Flanges using all kind of industrial high quality raw materials. We possess a large warehouse that enables us to keep huge stock of our products thus we provide a perennial supply of goods to our customers. Click Below Tabs to check country and city list.

| Afghanistan | Algeria | Angola |

| Argentina | Australia | Austria |

| Azerbaijan | Bahrain | Bangladesh |

| Belarus | Belgium | Bhutan |

| Bolivia | Brazil | Bulgaria |

| Canada | Chile | China |

| Colombia | Costa Rica | Croatia |

| Czech Republic |

| Denmark | Ecuador | Egypt |

| Estonia | Finland | France |

| Gabon | Ghana | Greece |

| Hong Kong | Hungary | India |

| Indonesia | Iran | Iraq |

| Israel | Italy | Japan |

| Jordan |

| Kazakhstan | Kenya | Kuwait |

| Lebanon | Libya | Lithuania |

| Malaysia | Mexico | Mongolia |

| Morocco | Netherlands | New Zealand |

| Nigeria | Norway | Oman |

| Pakistan | Peru | Philippines |

| Poland | Portugal | Qatar |

| Romania | Russia |

| Saudi Arabia | Serbia | Singapore |

| Slovakia | South Africa | South Korea |

| Spain | Sri Lanka | Sweden |

| Switzerland | Taiwan | Thailand |

| Trinidad & Tobago | Tunisia | Turkey |

| Ukraine | United Arab Emirates (UAE) | United Kingdom (UK) |

| United States (US) | Venezuela | Vietnam |

| Yemen |

| Aberdeen | Abu Dhabi | Afghanistan |

| Ahmedabad | Ahvaz | Al Jubail |

| Al Khobar | Algiers | Ankara |

| Atyrau | Bangkok | Bengaluru |

| Bhopal | Bogota | Brisbane |

| Busan | Cairo | Calgary |

| Caracas | Chandigarh | Chennai |

| Chiyoda | Coimbatore | Colombo |

| Courbevoie | Dallas | Dammam |

| Doha | Dubai | Edmonton |

| Ernakulam | Faridabad | Geoje-si |

| Gimhae-si | Granada | Gurgaon |

| Hanoi | Haryana | Ho Chi Minh City |

| Hong Kong | Houston | Howrah |

| Hyderabad | Indore | Istanbul |

| Jakarta | Jeddah | Karachi |

| Kolkata | Kuala Lumpur | Kuwait City |

| La Victoria | Lagos | Lahore |

| London | Los Angeles | Ludhiana |

| Madrid | Manama | Melbourne |

| Mexico City | Milan | Montreal |

| Moscow | Mumbai | Muscat |

| Navi Mumbai | New Delhi | New York |

| Noida | Perth | Petaling Jaya |

| Pimpri-Chinchwad | Port-of-Spain | Pune |

| Rajkot | Rio de Janeiro | Riyadh |

| Santiago | Secunderabad | Seoul |

| Sharjah | Singapore | Surat |

| Sydney | Tehran | Thane |

| Thiruvananthapuram | Toronto | Ulsan |

| Vadodara | Visakhapatnam | Vung Tau |

ANSI B16.5 / ASME B16.47 SS Slip-on Flange Used in

Utmost care is taken towards the packing of the Slip-on Flanges so as to ensure that the resultant Products reach in the same condition as desired by our customers from varied industries. We focus on every procedure to assure quality, the package we usually prefer is environmental poly bags, and then in free fumigation wooden cases or plate. Also can accept a customized package of Stainless Steel Flange such as OEM by negotiation. We offer just about everything to meet your 304/316 SS Flanges pack requirements. A Lot of emphases is placed on the packing and packaging. The SS ANSI B16.5 / ASME B16.47 SOFF Flange is packed in wooden corrugated boxes foiled in plastic wraps and bubble wraps. Below are Application Industries where we supply and export.