Aluminium Alloy Flat Bars, Aluminium 7075 Flat Bar, Aluminium Flat 7050 Bars Supplier, Aluminium 6061 T6 Flat Rods, ASME SB221 Aluminium 6083 Flat Bars Stock Holders, Aluminium 6082 Flat Bars Exporter, Aluminium Alloy 6063 Industrial Flat Bars, ASTM B211 Aluminum 6061 Flat Bars, Aluminium 5086/5083/5082/5754/5052/5005/ Flat Bar Extrusions, Flat Aluminium 3003 Bars, Aluminium 2024 Flat Bars Stockist, Aluminium 2017 & 2014 Flat Bar Stock, Aluminum 1100 Flat Bars Suppliers in Mumbai India.

Aakash Steel is largest Suppliers of Aluminium Alloy Flat Bars in Indian Popular Cities like Pune, Mumbai, Faridabad, Hyderabad, Chennai, Coimbatore, Kolkata, Ahmedabad, Bangalore, Chennai, Ghaziabad, Jalandhar, Jaipur, Ludhiana, Rajahmundry, Rajasthan, Vijayawada, Vizag.

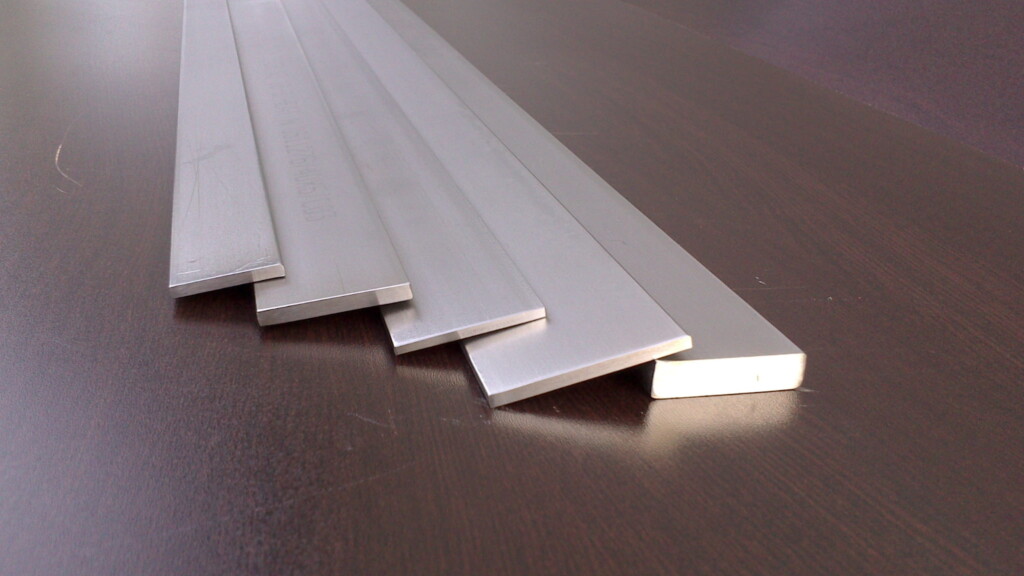

Aluminium is a versatile metal with numerous applications in various industries due to its lightweight, corrosion-resistant, and excellent thermal and electrical conductivity properties. One of the essential forms of aluminium is the flat bar, widely used in construction, transportation, aerospace, and manufacturing sectors. In this blog, we will explore the different grades of aluminium flat bars and their specifications, as well as their applications and global reach.

Grades of Aluminium Flat Bars

- Aluminium 1050 Flat Bar:

Aluminium alloy 1050 is a commercially pure grade with excellent electrical conductivity, making it suitable for electrical applications and general fabrication.

- Aluminium 1060 Flat Bar:

Similar to 1050, 1060 is also a pure aluminium grade with good formability and corrosion resistance, commonly used in chemical equipment and reflectors.

- Aluminium 1070 Flat Bar:

Aluminium alloy 1070 is known for its high thermal conductivity and is used in heat exchangers and radiators.

- Aluminium 1100 Flat Bar:

Alloy 1100 exhibits superior workability and high resistance to corrosion, making it suitable for chemical storage, kitchenware, and general sheet metal work.

- Aluminium 2014 Flat Bar:

This alloy contains copper and is known for its high strength and excellent machinability, used in aerospace components and structural applications.

- Aluminium 2017 Flat Bar:

With added copper and magnesium, 2017 offers high strength and machinability, commonly used in aircraft fittings and hardware.

- Aluminium 2024 Flat Bar:

Widely used in aerospace applications, 2024 is known for its high strength and fatigue resistance.

- Aluminium 3003 Flat Bar:

This alloy is commonly used for its moderate strength and good corrosion resistance, found in kitchen equipment and chemical tanks.

- Aluminium 5005 Flat Bar:

With excellent anodizing properties, 5005 is used for architectural and building applications, as well as in the automotive industry.

- Aluminium 5052 Flat Bar:

Known for its high fatigue strength and good weldability, 5052 is used in marine and transportation applications.

- Aluminium 5754 Flat Bar:

This alloy offers excellent corrosion resistance and is commonly used in shipbuilding and automotive industries.

- Aluminium 5082 Flat Bar:

With good weldability and moderate strength, 5082 is utilized in marine applications.

- Aluminium 5083 Flat Bar:

Known for its exceptional resistance to seawater corrosion, 5083 is used in shipbuilding and offshore applications.

- Aluminium 5086 Flat Bar:

Similar to 5083, 5086 offers high corrosion resistance and is used in marine environments.

- Aluminium 6061 Flat Bar:

One of the most popular general-purpose alloys, 6061 is known for its good mechanical properties and weldability.

- Aluminium 6063 Flat Bar:

This alloy is often used for architectural and extruded applications due to its excellent finishing characteristics.

- Aluminium 6082 Flat Bar:

With good machinability and strength, 6082 is used in structural applications and machining.

- Aluminium 6083 Flat Bar:

This alloy offers high strength and is used in marine and structural applications.

- Aluminium 6061 T6 Flat Bars:

The T6 temper of 6061 provides enhanced mechanical properties and is widely used in aerospace and structural applications.

- Aluminium 7050 Flat Bar:

With high strength and good resistance to stress corrosion cracking, 7050 is used in aerospace applications.

- Aluminium 7075 Flat Bar:

Known for its high strength-to-weight ratio, 7075 is widely used in aerospace and military applications.

Standard Specification and Export Countries

The standard specifications for aluminium flat bars include ASTM B211, ASME SB211, ASTM B221, ASME SB221, ASTM B565, ASME SB565, ASTM B316, ASME SB316, AMS 4102, and ISO Al99.0Cu. These standards ensure the quality and consistency of the material, making it suitable for various critical applications.

Standard: ASTM, ASME, AMS, GB/T, JIS

Length : 100 mm To 3000 mm Long & Above, Random, Fix & Cut Length or as per clients’ requirement

Size : 5 mm To 500 mm

Finish : Bright, Polish & Black

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Sheet

Aluminium flat bars are exported to numerous countries across the globe, including but not limited to Sri Lanka, Saudi Arabia, Oman, Kuwait, Netherlands, Iran, Bahrain, Qatar, UAE, various African countries, China, Nigeria, Mexico, Canada, Venezuela, the United Kingdom, the United States, South Africa, Malaysia, Bangladesh, Turkey, Singapore, Australia, Brazil, Germany, France, Italy, South Korea, Poland, and Belgium. This widespread export highlights the universal demand for aluminium flat bars in diverse industries.

Applications of Aluminium Flat Bars

The extensive range of grades and specifications for aluminium flat bars allows them to serve a wide array of applications, including:

- Construction:

Aluminium flat bars are used in structural components, frames, and supports due to their lightweight and excellent corrosion resistance, contributing to the durability and longevity of buildings.

- Transportation:

In the automotive, marine, and aerospace industries, aluminium flat bars find applications in various parts, such as door frames, body panels, and structural components, where weight reduction is crucial for fuel efficiency and performance.

- Electrical Industry:

High conductivity aluminium grades like 1050 and 1060 are utilized in electrical transmission lines, conductors, and bus bars.

- Manufacturing:

Aluminium flat bars serve as raw materials for the fabrication of a wide range of components, including fittings, extrusions, and machine parts.

- Architectural:

Aluminium flat bars are used for architectural trim, curtain walls, window frames, and door frames, as they can be easily extruded into complex shapes and finishes.

- Marine:

With excellent corrosion resistance, alloys like 5083, 5086, and 5754 are preferred for marine applications, including boat hulls and structures.

- Aerospace:

Alloys like 2024, 6061, and 7075 are widely used in aircraft structures, wings, and fuselage components due to their high strength-to-weight ratio and fatigue resistance.

Conclusion:

Aluminium flat bars are indispensable components used in a myriad of industries, owing to their exceptional properties and versatility. With various grades catering to specific requirements and standard specifications ensuring their quality, these flat bars are the preferred choice for construction, transportation, aerospace, and manufacturing applications. As global demand for aluminium flat bars continues to rise, their significance in modern industries remains unwavering.